To solve the bottleneck problem of straw biogas plants, DeTong cooperates with BEB Berlin for DeTong straw pretreatment and agitation technologies.

Advantages of Straw Biogas Technology

Pretreatment Facilities

The pretreatment for straw is the key process for the operation of a straw biogas plant. DeTong provides the straw raw material for pretreatment process concept aiming at different kinds of straw as corn, rice, or wheat straw.

DeTong´s straw pretreatment facilities are able to shred, extrude, mix, and to feed the substrate into the digester, safely and stably. Multiple assemblies would be provided by DeTong, according to different kinds of pretreatment processes, to meet the requirement of raw material quality.

Agitation Facilities

DeTong straw agitation facilities are made up by a vertical flow guidance agitator and at least one horizontal agitator. The floating material would be sucked to the bottom of the digester by the tube of the vertical agitator, to entirely mix the substrate. DeTong agitation system is reliable, stable, energy saving, and able to solve various problems for straw biogas plants.

Further Details

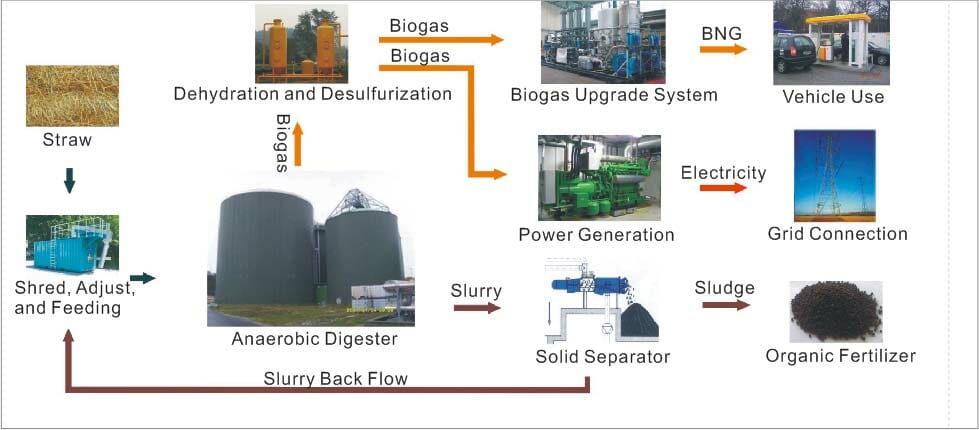

A straw-biogas project employs straw as the principal raw material, which is subjected to anaerobic digestion in order to produce both biogas and biogas fertilizer – The former is utilized in rural production and livelihood so as to improve the living conditions of rural households, while the latter realizes the “waste-to-manure” transition process thus improves the fertility of soil. Straw-biogas projects can not only protect ecological environment but also serve as a main measure for both agricultural energy saving & emission reduction and development of renewable energy sources.

Main Processes associated with Straw-Biogas Projects:

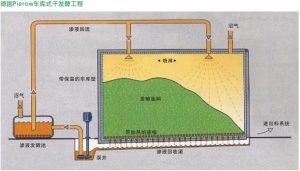

- Garage-Type Dry Digestion Process (Anaerobic Solid State Digestion Process or ASSD)

- Completely Mixed Continuous Anaerobic Digestion Process (CSTR)

- Completely Mixed Self-Carrier Bio-Film Anaerobic Digestion Process (MMSB)

- Vertical Plug-Flow Anaerobic Digestion Process (VPF)

- Combined Two-Phase Anaerobic Digestion Process (CTP)

- Membrane-Covered Trough Anaerobic Digestion Process (MCT)